Solutions for body building

Truck body builders have to meet stringent demands today. Demand for new and more efficient transport solutions and solutions that meet complete new transport needs is pushing development. This means that innovation and the ability to quickly convert creative ideas into finished products are essential requirements. But at the same time it is vital to comply with the relevant standards and regulations.

Substandard truck bodies and structures can endanger safety on our roads and pose high risks to drivers and those who carry out loading and unloading. So it easy to understand why the field is so tightly regulated. In addition to European standards, there are local regulations, which harmonize with each other to varying degrees. Familiarity with these rules is essential for anyone involved in the industry.

Customized solutions

Forankra is well aware of the everyday life of body builders thanks to long-term cooperation with body builders of light and heavy transport vehicles. Together, we initiate and develop quality-assured solutions that optimize the load volume, enable transport of temperature-sensitive goods and that can create flexibility in the utilization of the loading area.

Our product range includes cargo securing tracks and systems, double decking systems, cargo bars and shoring beams, mobile thermo-walls for variable temperature zones in refrigerated vehicles, and a complete range of cargo securing equipment that is normally supplied with the vehicle.

For lightweight cargo vehicles (LCV) we offer the most innovative dropside locking pillar system on the market – Armaton – known for its high quality, attractive design and low weight. Armaton has also developed a unique concept for a modular flatbed system, the Armaton Modular Platform.

Double decking

With double levels of loading, higher volume utilization and better transport economy are obtained.

Safe refrigerated transport

By choosing the right thermo product it is possible to obtain safe transport of frozen and refrigerated goods as well as frost-sensitive goods.

Double decking

Double decking is a beam/track system, which means that you load the goods in two levels and thus can transport double the amount of goods - provided the weight allows it.

Safety

The biggest risk with dubble cargo levels is the increased risk of overturning. To reduce the risk of overturning, it is important to ensure that the center of gravity is as low as possible. This requires that the driver knows or can correctly estimate the weight of the load, otherwise the risk of overloading is high.

When loading, it is important that the upper level is loaded first and when unloading, the goods on the lower level must be unloaded first. This can sometimes lead to the necessity of reloading, when the lower plane is empty, in order to bring the center of gravity down to an acceptable level. Avoid driving with a load on the upper level if the lower level is not fully loaded.

When securing loads on cargo carriers with double load levels, the same rules apply as when securing loads on one level, i.e. that all goods are secured so that they cannot tip or slide. The goods must be blocked at the front, back and sides. The safety must withstand the full load weight forward and half the load weight backwards and sideways.

Working environment

The working environment when loading and unloading is not the best, as the standing height of the truck bed is limited. One way to improve the working environment is for the truck or trailer to be equipped with a ceiling that can be raised and lowered. To avoid the risks involved in handling the manual double decking system, you can use long ceiling tracks when the booms are to be parked in the ceiling. With long ceiling tracks, the operator can remain on the floor and insert/remove the boom from the track safely and quickly.

Another work environment risk is the noise level. A Double decking system consists of metal parts, which produces a high noise level when in use. To reduce the noice level, Forankra has developed a Double decking system, which is Piek-certified in accordance to EU directive 2003/10 / EC 20030206. This means that the system has a noice level below 60dB.

For better sliding and reduced noise level, it is also recommended that wall and ceiling tracks are lubricated with e.g. Lithium grease spray or, if it is to be food approved, Würth's food spray oil (0893 1071-c/s).

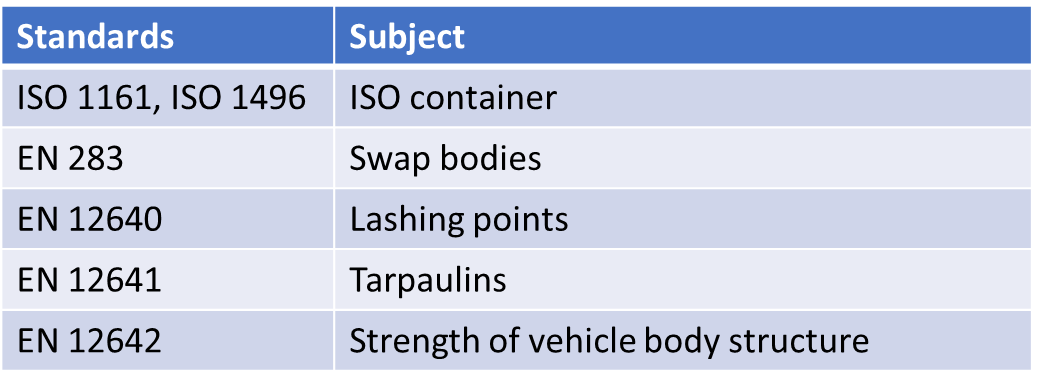

Regulations for body building

Body building is strictly regulated by both European standards and local regulations. The regulations are designed to minimize deficient body building and constructions, which can endanger the safety of our roads.

For your information

With Forankra as partner, you can be sure that the products are

manufactured in accordance to current legislation and standards.

Our experts are available for questions and advice as well as for recommendations of solutions adapted to your needs.

Our services

Forankra offers several services for body building:

• Training in cargo securing and cargo optimization

• Counseling

• Customized products and solutions

• Regulations and documentation