Chain for lifting

General info about chains

Chains are available in different grades and standards (see table) where the choice most often is based on the area of use. The most common standards are DIN and SMS as well as G80 and G100. Chains is also divided into short link or long link. This applies to both DIN chains and classified lifting chain (grade 80 and 100).

MS chain stands out as it is divided into three groups, short link (KL), half-long link (HLL) and long link (LL). For classified lifting chains, there are only established measurements for short links. The link lengths between the different standards and length groups are not consistent.

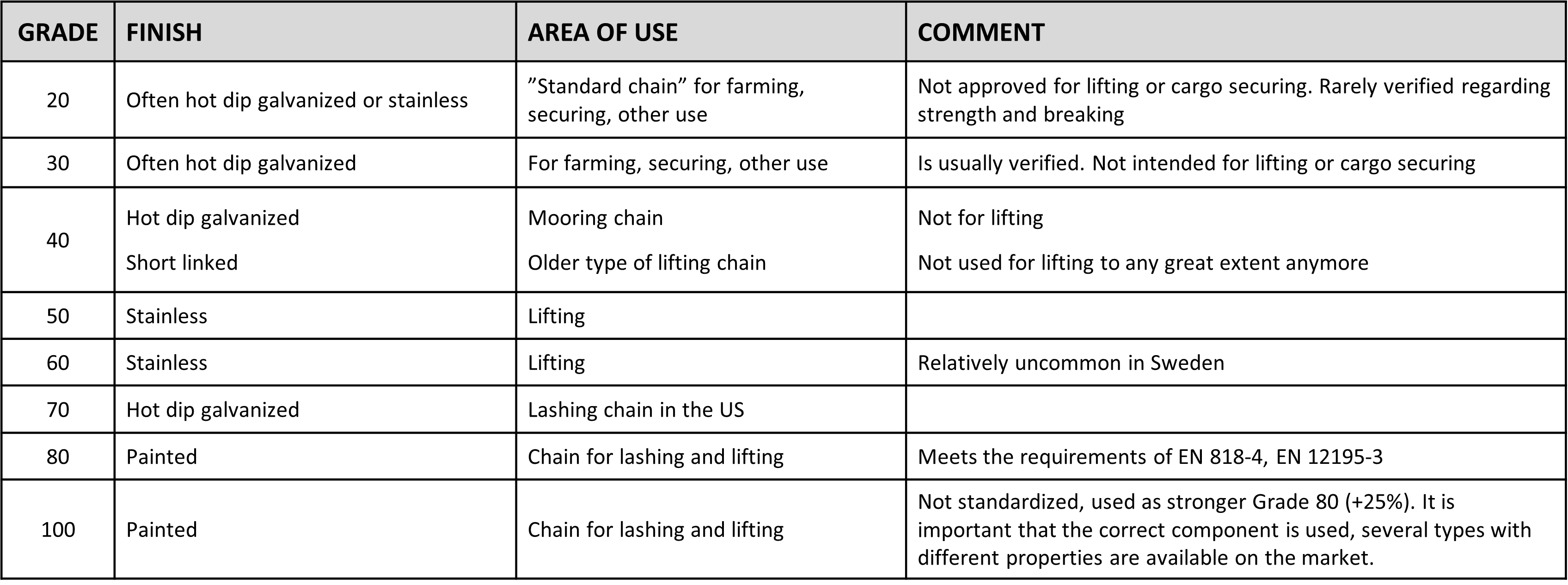

In addition to these chain types, there are a number of variants in different grades, where the grade states the strength of the chain material. The table below shows the most common chain types.

Chains - Areas of use

Chain for safe lifting

Lifting equipment is regulated in the European Machine Directive 2006/42/EC. Far-reaching requirements are set here to meet basic safety and health requirements. In Europe, a number of harmonized standards have been developed to more easily meet these requirements. For lifting chain equipment, there is the EN 818 standard suite where both the complete equipments and the chain itself are regulated.

In addition hooks and any other components for the lifting chain are regulated in EN 12195-3 and must be classified for lifting.

The standard for chain lashing is relatively old and is due for revision. The current version covers only chain and components in Grade 80, but the use of Grade 100 is being used more and more. There is today an on-going process to standardize chain and components Grade 100, which are currently available in up to three different versions.

It is important to choose the right Grade 100 chain and components as the difference from Grade 80 only should be that the strength is 25% higher than Grade 80. Wrong components and/or chain can, for example, lead to brittleness at low temperatures.

Chain Grade 20

Chain Grade 20 is a standard and usually galvanized chain that is often found in hardware stores. Chain Grade 20 must not be used for cargo securing or lifting. It usually follows DIN standards or have SMS measurements. The stainless steel chains you find in hardware stores are normally also in Grade 20 quality.

Chain Grade 80 and Grade 100

Chain Grade 80 chain is approved for both cargo securing according to EN 12195-3 and for lifting equipment according to EN 818-4. A long link chain is exposed to excessive force over for example an edge. Therefore, only short-chain chains are approved in these standards but with one exception – long linked chain may be used for cargo securing of round timber transports in dimensions 6, 9 and 11 mm.

Grade 100 is a stronger quality and is also used for cargo securing and lifting. The measurements are according

to Grade 80 but the strength is 25% higher for Grade 100 compared to Grade 80.

Chemicals

In general, you should avoid exposing chain and components to acids or other aggressive chemicals. This can affect the strength but also result in increased brittleness etc. Chains in Grade 80 and Grade 100 must not be used in contact with acids or other aggressive chemicals. The device must not be exposed to galvanizing.

Handling and control

It is important that the chain is handled correctly during use and that deformation and wear are regularly checked. The chain must be protected against sharp edges. A chain that has a bent or otherwise deformed link must be discarded as it is severely weakened. Also be vigilant about wear and tear. The procedure for measuring wear can be found below.

An elongated link has probably been overloaded. Chain and components are designed so that it is obvious, in time, that they have been elongated under excessive load to avoid a sudden rupture and failure. A chain or component showing signs of elongation must be immediately removed from service.

To consider when handling chains:

• Only use a classified chain for lifting and cargo securing

• Use shortening hook when adjusting the length of the chain

• Knots may not occur on the chain

• Protect against sharp corners by using suitable shims

• Chains must not be exposed to excessive heat

• Avoid jerks when applying load to a chain

• Never apply the load at the tip of a hook. The load should always be at the bottom of the hook

• The different components should always be able to move freely in the direction of the load

Replace the chain equipment:

• When there are signs of permanent elongation, deformation, cracks or other indication occurs

• When wear on the chain measured in 2 perpendicular directions (d1, d2) exceeds 10% of the original dimension (d normal) according to the formula here:

Definitions of terminology used for chains

Test force (MPF)

The force with which an equipment or component, which is going to be tested, is tested with before delivery. The force varies depending on the product and the controlling standard and is usually 1.25-2.5 times higher than the maximum working load (WLL).

Breaking force (MBF)

The force at which the chain breaks during destructive testing.

The total elongation

Measurement of total increased length of the material when breaking, expressed in %.

Maximum work load (WLL)

Maximal work load of the product (classified lifting components)

Safety factor (SF)

The relation between breaking force and maximum work load for a material