How to ensure the right choice of soft lifting equipment

Safe lifting always starts with choosing the right equipment. The choice of lifting equipment depends on what you intend to lift. Lifting equipment is often divided into two groups - hard lifting equipment and soft lifting equipment. Here we describe what you need to consider when choosing soft lifting equipment.

See our complete range of Soft lifting equipment.

Soft lifting equipment is used for fragile goods and is especially useful when you want to snag the load during lifting. Round slings, webbing slings and eye-eye webbing slings are most often used separately, without other lifting equipment, but can be combined with Grade 80 and Grade 100 lifting equipment if needed. This type of equipment is very versatile as it can be attached to the load in many different ways. Soft lifting equipment has a soft surface that is in contact with the goods, i.e. it does not damage the goods.

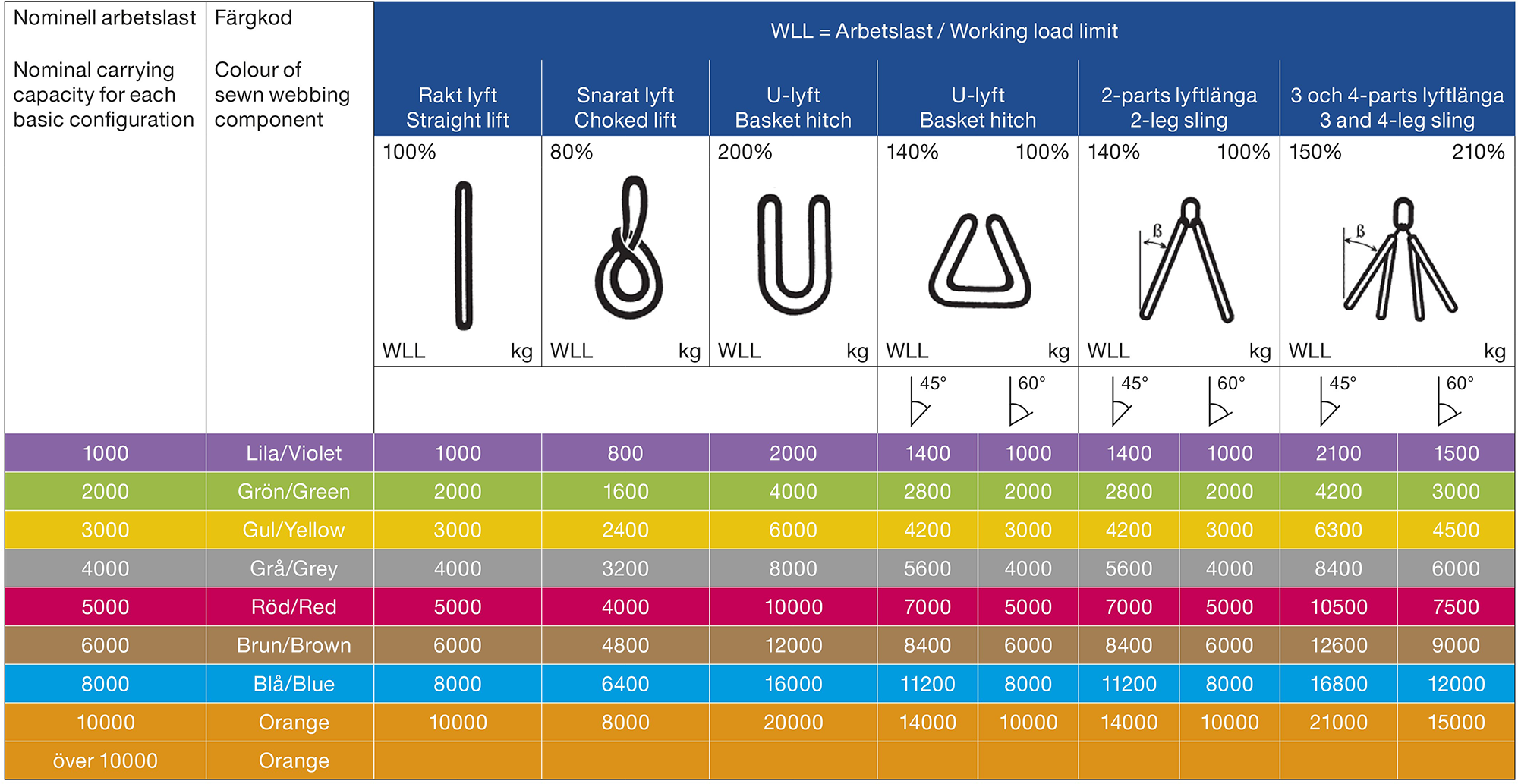

The vast majority of soft lifting devices are manufactured according to a standard harmonized with the European Machinery Directive and are then color-coded for their maximum working load limit (WLL).

Round sling with our without side seam?

At Forankra AB you find round slings with or without side seam. Round slings with side seam are a bit tighter and stiffer which can be of advantage if e.g. the sling is to be inserted under a pallet or load. A seamless round sling is in general a bit softer and floats out more and thereby widen the contact surface. Round slings with double coating (Duplex) has significantly higher wear resistance.

CE-marked lifting sling

Lifting accessories produced after January 1st 1995 must be CE-marked. The CE-marking is a proof of the compliance with the European Machine Directive. User manuals and declaration of conformity must be attached to each delivery.

What is EN 1492-1 and -2?

Lifting slings marked with EN 1492-1 or -2 are produced according these European norms. They are among other things color-coded, tested and in compliance with high requirements. If a sling is in accordance with these norms it is also in compliance with the machine directive.

Round sling

Roundslingstropp

Endless webbing sling

Webbing sling eye-eye

Things to keep in mind when using soft lifting equipment:

• Soft lifting equipment is easily damaged by friction or abrasion against sharp edges. You should therefore use corner protection in these situations.

• Lifting components in combination with soft lifting equipment should always have rounded edges with a well-sized radius.

• Avoid sudden jerks as frictional damage otherwise can occur.

• Use lifting equipment that has an inner radius that is at least equal to the width of the webbing.

• Lift vertically and make sure that the load is symmetrically distributed.

• Soft lifting equipment should not be used when lifting goods that are hotter than 100°C.

• Make sure that soft lifting equipment does not come into contact with alkaline chemicals.

• Never shorten soft lifting equipment with knots.

• Never overload – stay within the working load limit (WLL).

• Make sure you have access to the correct documentation before you start using the lifting equipment. For example, there are many certificates and user instructions available for download on the Forankra website.

• Get to know your lifting equipment – read the user manual.

When should soft lifting equipment be replaced?

Round slings

Examine the entire sling and check that there are no irregularities inside. Also check that the cover is undamaged and that the label is legible. Discard the sling if there is any damage to the protective fabric.

Webbing slings / eye-eye webbing slings

Examine that the seams are intact and that the label is legible. Discard the lifting equipment if eye protection has worn out. If there is any edge damage or transverse damage to the webbing, discard the equipment immediately.

Always be aware of any type of damage on the equipment. If there are signs of wear, friction damage or chemical impact, the specific equipment should be taken aside for examination.

Working load limit (WLL)

Calculation of working

load limit (WLL)

Soft lifting slings are color-coded based on the working load (WLL) they are rated for. The WLL is reduced or increased based on how the sling is applied on or around the item to be lifted. See table.