Transport of temperature- and moisture-sensitive goods

Temperature sensitive goods

Goods such as foods, drugs and chemicals are often temperature sensitive or sensitive to temperature variations. Incorrect temperature can lead to major financial losses in the form of damaged goods and, in particular, consequential costs in lost business and customer relations. Temperature-sensitive goods can be transported in climate-controlled cargo carriers, alternatively in standard carriers, if the goods themselves are well-insulated. The choice of method depends on the type of goods, quantity, frequency, need for reloading and type of cargo carrier.

Forankra offers various systems for handling temperature-sensitive goods, such as movable partitions for refrigerated vehicles and thermo pallet hoods. With movable partitions, different temperature zones can be created quickly and efficiently, which increases the vehicle's possible loading capacity. Thermal pallet hoods are used to temperature-proof pallets, roller cages and other types of goods.

Moisture-sensitive goods

Moisture damage on goods occurs most often during transports, loading/unloading and temporary storage at terminals. Temperature variations are difficult to remove but by using desiccants to remove moisture from the air, you can prevent the build-up of moisture to levels where it may cause damage.

The costs for damaged goods due to moisture during transport are unpredictable and can be very expensive. Insurers estimate that approximately 12% of all container shipment damage is moisture-related.

Forankra’s product range includes desiccant for two application areas:

• Desiccants for positioning inside the cargo carrier/container

• In-box desiccants for positioning inside products cartons and boxes

Recommended product groups for temperature- and moisture-sensitive goods:

Solutions for temperature-sensitive goods:

Partition walls for separating temperature zones in refrigerated vehicles

The use of thermo walls enables the handling of goods, which require an even and maintained temperature throughout the transport. There is a wide range of thermo-walls, which are designed to suit different areas of use. Long-distance transports, which handle refrigerated goods during longer transports, require different solutions than distribution trucks, which drive short distances with many stops.

For refrigerated trucks, Forankra offers a number of systems of movable partitions for dividing the transport space into different temperature zones. Frozen goods and refrigerated goods can then be transported on the same carrier, which increases both flexibility and loading capacity while transport costs and environmental impact can be reduced.

For distribution trucks, sliding walls can often be a quick and flexible solution for temporary handling of refrigerated goods.

The choice of thermo wall is based on the requirement of the specific transport, i.e the cargo carrier and the need of refrigeration. All walls are easy to handle and the driver can quickly change the temperature zones to the actual need.

Thermo walls are available in different designs:

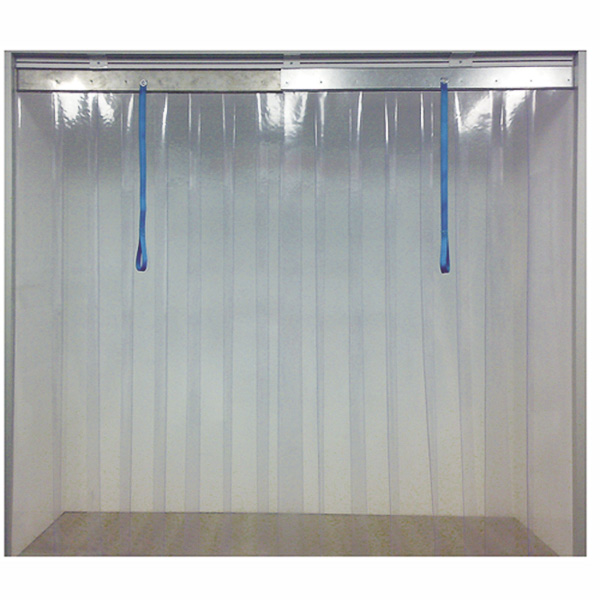

• Soft thermo walls – are not dimensionally sensitive during installation. Applied with lintel and a cargo bar

• Semi-hard thermo walls – requires sizing for each unique cargo carrier. Applied with two or more cargo bars

• Hard thermo walls - applied with integrated gas spring construction

Forankra manufactures all thermal walls in Vårgårda after received orders. This gives us the opportunity to adapt the walls to the customer's specifications and special solution.

Soft thermo walls

Semi-hard thermo walls

Hard thermo walls

Thermo pallet hoods

Forankra offers a wide range of high-performance insulating thermo pallet hoods of the highest quality. We store and can quickly deliver hoods for roller cages and EUR pallets at different heights. In addition to our standard pallet hoods, we can customize the hoods format to required measurements. With our highly insulating thermo-hoods, frozen goods can maintain the desired temperature up to 48 hours. Materials used in the hoods comply with food management requirements according to FDA, PGI, and REACH.

Material properties

Our hoods are manufactured by COMBI-THERM, whose unique POLYWOOL® insulation material guarantees long life with retained insulation properties. The patented fiber has a unique resilient Zic-Zac shape, which is not deformed under pressure. The fiber always springs back and guarantees a full and insulating air layer in the material over time. The hoods can be manufactured in different foils depending on the desired properties.

Our standard hoods are made of a metal foil, which has very good reflective properties while being very resistant to abrasion and demolition. Up to 90% of solar radiation energy is reflected by this material. In other words, the foil combines excellent radiation protection with very good mechanical properties. The insulation material consists of 300gram / m2 POLYWOOL®.

Application areas

Insulating pallet hoods allow time-limited transport of temperature sensitive goods on regular cargo carriers, but also protection of the goods during reloading or waiting time at the terminal or at another temporary storage. Through the use of thermo-hoods, a comprehensive, cost-effective and environmentally-friendly alternative to energy-intensive refrigeration vehicles is obtained. The hoods are also a cost-effective solution for shorter distribution of food in LCV, which is now increasing as a result of internet commerce. Transports of chemicals, such as paint and drugs, are other common uses.

Thermo pallet hoods – tips before use

The pallet hood has very good insulating properties, but in order to avoid thermal conduction through convection, airflow through the bottom of the pallet must be prevented. This is done easily by first placing an insulating layer at the bottom of the pallet before the goods are placed on the pallet. Often it is enough with a corrugated board. More optimal is a bottom piece of the same insulating material as the pallet hood itself. This stops airflow, which otherwise acts as a thermal pump. It is also important that the hood is as close to the goods as possible to avoid air pockets inside the pallet.

Facts about termal transmission

Thermal transmission is the transport of thermal energy that occurs due to temperature differences between two different bodies.

Thermal transmission occurs through conduction, convection and radiation.

• Thermal conduction occurs mainly in solid materials and is due to a temperature gradient leveling out.

• Convection occurs as a result of the movement of a fluid that also redistributes heat. At convection, at least one phase is a fluid.

• Radiation occurs regardless of whether the media phase is gas, liquid or solid and it does not require a transport medium.

Solutions for moisture-sensitive goods

Desiccants

A desiccant is a hygroscopic material that absorbs water molecules from the surrounding air, decreasing the levels of moisture. Desiccants are used in situations where excess moisture can cause damage, especially during transport and storage, and can be used for any product that can be damaged by moisture.

Desiccants are usually available as a desiccant pouch that contains 1-200 g, which is used as in-box protection I cartons and boxes. Larger desiccants are often used to protect goods shipped in cargo carriers / containers from moisture damage.

High absorption inbox desiccants

Forankra’s Absorgel Pouches consists of pouches which are absorbing moisture inside of cartons and boxes, to prevent moisture related damages to the packed goods. The active ingredient in the Absorgel Pouch is calcium chloride, which has a superior ability to absorb moisture from the surrounding air. The absorbed water is bound into a gel so that no liquid water is formed.

Absorgel Pouches can be used for almost any type of goods that requires moisture protection. Absorgel Pouch with one layer of packaging is mainly used for crates and larger boxes, while Absorgel Pouches with two layers is preferred for smaller cartons and when the pouch will be in direct contact with the cargo.

Desiccants for reducing moisture inside cargo carriers/container

Forankra's range of desiccants for reducing moisture inside cargo carriers/containers can be divided into two groups – horizontal and vertical desiccants:

• The vertical desiccants can be hung on the inside wall of the cargo carrier without interfering with the goods. This includes Absorgel Hanging and Absorpol.

• Absorgel Blanket is a horizontal absorbent, which can be placed on top of goods and pallets.

The desiccants that convert moisture into gel, i.e. Absorgel Hanging and Absorgel Blanket, can be used both horizontally and vertically. Absorpole offers effective moisture protection during longer transports. The absorbed moisture is transforded into a liquid which is collected in the blue container at the bottom, which means that it can only be used vertically.

For your information

With Forankra as partner, you can be sure that the products are manufactured in accordance to current legislation and standards.

Our experts are available for questions and advice as well as for recommendations of solutions adapted to your needs.

Our services

Forankra offers several services reated to temperature- and moisture-sensitive goods:

• Training

• Counseling

• Customized products and solutions

• Regulations and documentation