Cargo securing for distribution trucks

In Sweden, more than 40 million goods transport journeys are made each year, carrying more than 445 million tonnes of goods. The vast majority of goods are transported by distribution truck, in other words a truck that transports goods from a central warehouse to different recipients within the same region. Securing cargo in distribution trucks is the most difficult task of all, as they carry such a variety of goods, have many stops in each distribution round and they work to tight deadlines.

Methods and products for securing cargo in distribution trucks

The most common types of goods that distribution trucks carry are pallets of mixed goods and trolleys loaded with dairy products or packages, for example.

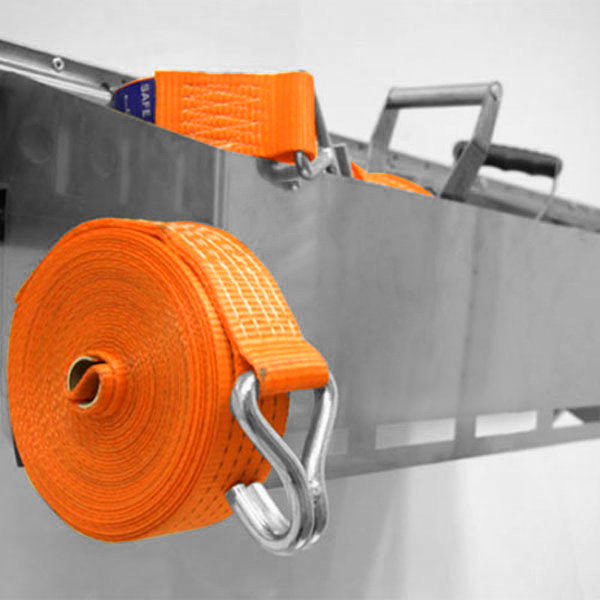

The most widely used methods of securing cargo in distribution trucks are blocking and lashing. Products that are often used for securing goods in a distribution truck are inside lashings and cargo bars. These can also be combined with lashings, corner protection, friction mats, pallet truck stops and pallet lift straps. It is also useful to have aids such as webbing winders and smart storage on hand.

Knowhow in Cargo securing

For more information about cargo securing, choosing correct equipment and product labeling, we refer to the section Cargo securing – Knowhow as well as to our “Guideline to Cargo Securing”.

Recommended product groups for cargo securing in distribution trucks:

Tips!

• A wide variety of track systems are fitted to the floor and walls of distribution trucks by manufacturers. By checking which system is fitted to your truck you can ensure you have cargo securing equipment that lets you use your cargo carrier to its full potential.

• Keep a box or Bandibag for storing your lashing straps, so they are close to hand when you need them.

• Fit a holder for a broom and shovel that fits your wall track.

• Use a pallet truck stop and pallet lift straps to prevent a pallet truck from moving about during transport.

• Remember that the floor surface should be kept clean to maximize friction.

• Make sure you have approved products with sufficient cargo capacity to secure your goods.

• In many situations it is useful to have a cargo bar with a cargo hoop, as this can replace several cargo bars.

• Shoring poles and beams can also be fitted at the rear of the cargo space, close to the rear doors, to prevent goods from falling out when you unload after a journey.

Inside lashings are used to secure the cargo in lashing points inside cabinets. Check which track system and lashing brackets the cargo carrier has, so that you choose inside lashing with right end fittings.

Cargo bars are used for vertical blocking and to easily block and separate goods on the cargo carrier. Goods support equipped with a cargo hope makes it easier to cover goods with a larger surface, for example boxes on a pallet.

By knowing which track system the truck has, you can ensure that your equipment has correct end fittings.

Use pallet truck stop and pallet lift straps to ensure that the pallet fork is held in place during transport.

With Bandibag, you can store your lashings, so that they are easily accessible when you need them.