Cargo securing in long-distance truck with closed cargo carrier

Around 25 percent of all goods transported in Sweden are carried by long-distance trucks between different regions – accounting for over 11 million journeys each year. The goods that are transported most frequently by long-distance trucks with a closed cargo carrier are pallets of mixed goods, often loaded in double decks.

Methods and products for securing cargo in closed cargo carrier

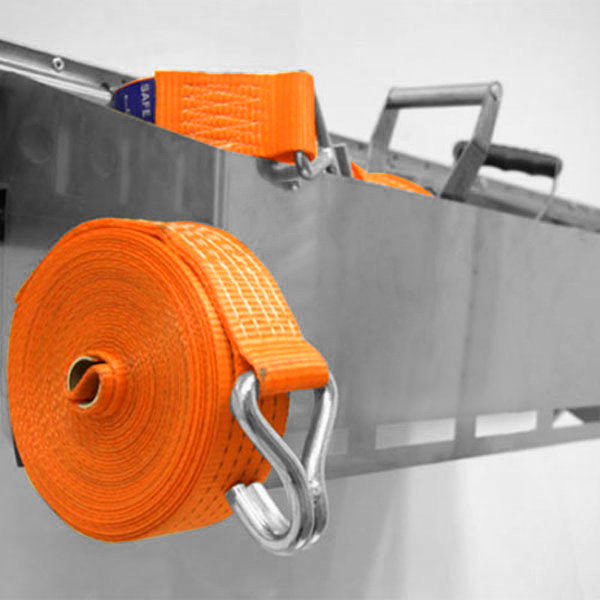

The most widely used methods for securing goods in a closed cargo carrier are lashing and blocking. Products that are often used for lashing are 50 mm lashings. In the case of blocking, cargo bars, shoring poles and shoring beams are used. It is also useful to have aids such as corner protection, Multi-Stick, friction mats, webbing winders and smart storage on hand.

Knowhow in Cargo securing

For more information about cargo securing, choosing correct equipment and product labeling, we refer to the section Cargo securing – Knowhow as well as to our “Guideline to Cargo Securing”.

Recommended product groups for cargo securing in closed cargo carrier:

Tips!

• A wide variety of track systems are fitted to the floor and walls of closed cargo carriers by manufacturers. By checking which system is fitted to your truck you can ensure you have cargo securing equipment that lets you use your cargo carrier to its full potential.

• In addition to using shoring beams and cargo bars for blocking, you can also use a double decking beam if this is available for the cargo carrier. Shoring beams and double decking beams are locked to the track, which gives them a higher blocking capacity (BC) than a cargo bar with a rubber-clad foot.

• Double decking is a cost-effective beam/track system that lets you load goods on two levels and permits the transport of a considerably larger amount of goods. Double decking also lets you stack fragile goods on two levels without the need to stack pallets on top of each other.

• Use a tension meter to ensure that your lashings have the correct tension.

Different track systems

Manufacturers of closed cargo carriers have different types of track systems for floor and inside walls. By knowing which system is in your truck, you can ensure that you have relevant cargo securing equipment available, which makes it possible to use the cargo carrier's full potential.

Blocking

When blocking you can, in addition to cargo bars, also use a double decking beam if this is available in the cargo carrier.

Shoring beams / double decking beams are locked in the rail and thus have a higher blocking capacity (BC) than a cargo bar with a rubber-covered foot.